|

|

|

|

|

|

Dust-free, high-density granules.

Uniform pellet-shaped particles.

High throughputs.

Mixing/granulation in the shortest possible time.

Economic process.

Low air/gas requirement.

Processing of different starter products.

|

| |

| |

Process advantages

VG wet granulation is an important technology for the manufacture of

granules, pellets and tablets. Granules from vertical granulators (also forced,

moist or wet blenders) are distinguished by a compact structure with good flow

characteristics, as the product is mechanically compressed during the

process. |

|

|

|

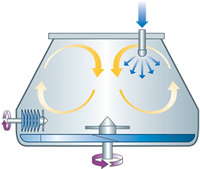

Principle of operation

For this process, Glatt offers Vertical Granulators with batch sizes from

100g to 1t/batch.

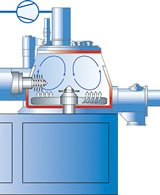

The technical design of the process has a significant effect on the

properties of the end product. In the Wet

Granulation process, powder is presented in a vertical granulator and

subsequently moistened or sprayed with molten material. The shear forces

produced by the Z-shaped rotor blades lead to an intensive mixing of the powder

and, with the addition of binder solutions, to the rapid formation of

high-density granulates. The chopper on the side wall of the container assists

the formation of larger agglomerates.

|

Single Pot process:

With smaller batch sizes (up to 800l) and/or

frequently changing products, granules can also be dried and cooled in the

vertical granulator. The major advantages lie in the gentle product handling in

vacuum up to 10mbar and the comparitively small

processing area, which can be cleaned very quickly and easily. |

|

|

|

|

In systems using the Single Pot method, the container is designed with a double

wall and can be connected to a solvent separator system. Additional

gas-stripping by means of nozzles in the lee of the rotor blades considerably

accelerates the drying of the particles.

|

| |

|